MS640: Motion Monitor for Secure and Redundant Control of Drive Systems

The reliable Motion Monitor MS640 provides a high degree of internal and external security. It is used for the logical and plausible monitoring of motor revolutions and the associated drive-side machine movements.

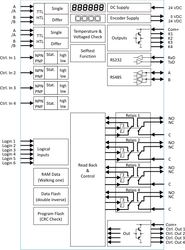

The device detects the actual states directly at the drive and at the periphery, compares these with the programmed setpoint states. If the movement is not plausible or if limit values ??are exceeded, the MS640 triggers the user-programmed fault message via the outputs. Furthermore, the monitor allows the permanent actual value detection on both rotary encoders (speed, direction of rotation, standstill, actual position and position difference).

- High level of external safety (Recognition of electrical or

mechanical errors in the machinery / sensor systems / wirings etc.) - High level of internal safety (detection of internal errors

and failures of the device components) - 2 Pulse inputs with format A, B, 90° [HTL] or A, /A, B, /B [RS422]

- 4 control inputs for PNP / NPN / Namur signals [10 ... 30 VDC]

- 6 logical inputs for PNP signals [10 ... 30 VDC]

- Input frequency up to 500 kHz

- 4 fast transistor outputs with push-pull characteristic,

short-circuit-proof [5 ... 30 VDC] - 4 forced-guided redundant output relays with

potential free change-over contact - Serial interface RS232 and RS485

- Power supply 24 VAC and 17 ... 40 VDC

- Compact norm panel housing

- 6 digits LED display with 15 mm height

- Display range -199999 ... 999999

- Setup by keys or PC via serial RS232 Interface

- Dimension B x H x T = 110 x 48 x 140 mm (4,33 x 1,89 x 5,51")

Declaration of Conformity

File type: pdf, File size: 162 KB

File type: pdf, File size: 1 MB

Data Sheet MS640

File type: pdf, File size: 385 KB

SM600: Mounting Clamps and Brackets

suitable for display units with front dimension 96 x 96 mm.

Show details »

« Back to overview