IO-Link systems

The whole world is talking about Industry 4.0 and IIoT. The Industrial Internet of Things (IIoT) means that every device is linked and communicates with each other in a value creation process.

This has many advantages, for example:

- Easy commissioning thanks to the plug & play principle of all participants

- Control / fieldbus and provider independence

- Minimization of downtimes by demand-oriented maintenance - thanks to condition monitoring

- The process data and parameters can be retrieved and adjusted from anywhere in the world

A basic requirement for Industry 4.0 is a uniform communication system for all participants. IO-Link is such a standardized communication system. The special thing about IO-Link is that not only the controller communicates with the sensors, but also the sensors can send their status to the controller.

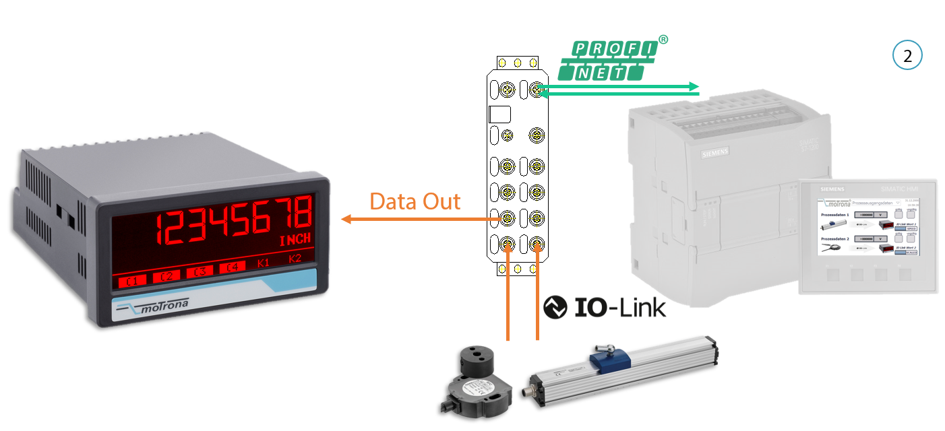

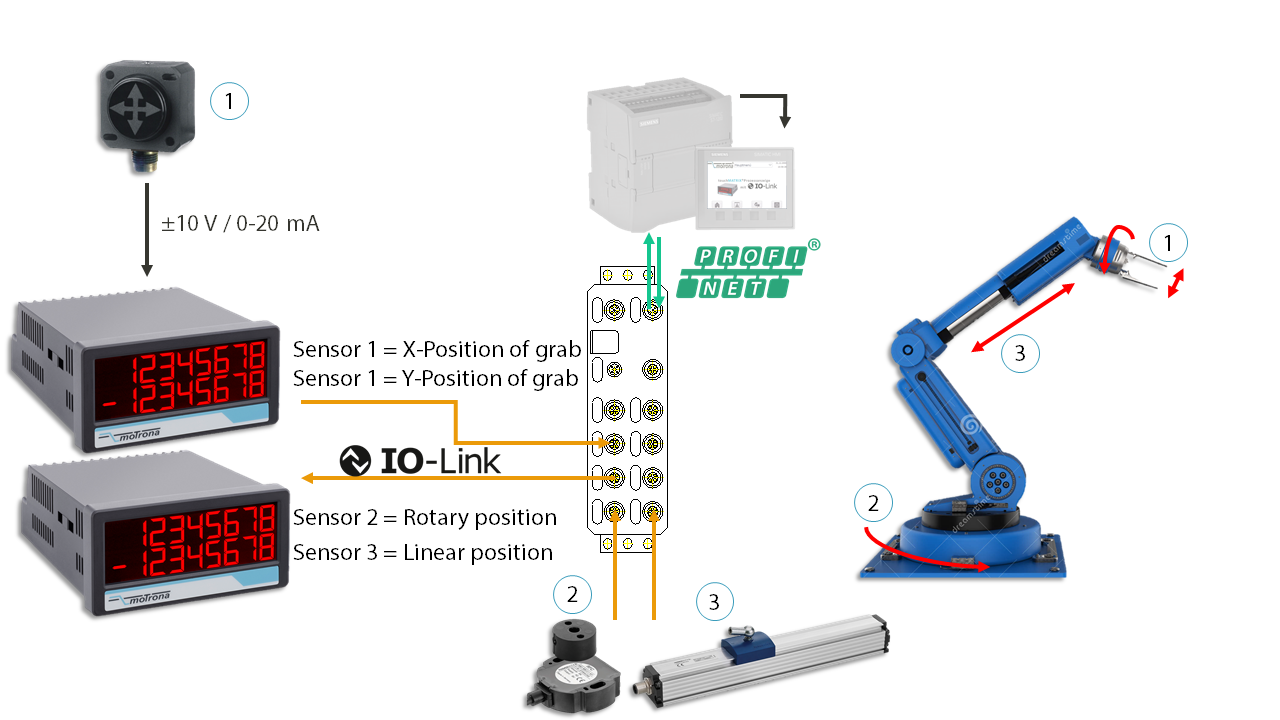

An IO-Link system consists of an IO master, several IO devices/slaves and a controller. The IO master bundles the information from the sensors (IO slaves) and passes them to the controller via any Bus interface (Profinet, EtherCat, Ethernet / IP, Profibus or AS-Interface) . Every IO device can be clearly identified by its IODD. This IO device description can be read out centrally by the controller.

With the AX350/IO, motrona has an IO-Link capable process display in its product range. The process display is very versatile. For example, it can be used to display analog process data, which it then passes unchanged on to the controller via the IO-Link master (Figure 1). But it also can perform various arithmetic operations (scaling, linearizing, adding, subtracting, multiplying, dividing, averaging, ...) with the data provided by the IO-Link master (Figure 2).